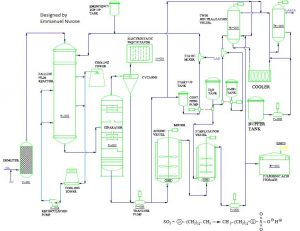

LABSA (Linear Alkyl Benzene Sulphonic Acid) is produced by the sulphonation reaction of Alkyl Benzene with Sulphur trioxide (SO). Some other processes might desire the use of Oleum or Sulphuric acid. The final decision will depend on various factors which might include the availability of raw material, location of the plant, the size of the plant, operation mode of the plant, to mention a few. Nevertheless, considering major factors such as cost, availability, flexibility and safety, SO still remains the preferential reagent for the reaction which is as shown on the flow sheet.

LABSA (Linear Alkyl Benzene Sulphonic Acid) is one of the major active ingredients for the production of soaps and detergents. Importantly, it forms a greater percentage of raw materials for the production of liquid soaps. Its major producer includes Chemithon and Ballestra. Similar steps are used by both companies to produce LABSA (Linear Alkyl Benzene Sulphonic Acid). However, the technology is slightly different especially at the sulphonation stage where Chemithon utilizes the Falling Film Reactor or Jet Reactor while Ballestra employs the Stirred Tank Reactor/Cascade Reactor or Multitube Falling Film Reactor.

The flow diagram shown utilizes the principle of Falling Film Reactoror or can be replaced with Multitube Falling Film ReactorThe Amount of electricity that would be consumed by the plant is dependent on the location of the plant and the total design of the plant and electrical configuration of the electrical components of the plant. It is difficult to get the total electrical consumption without the total design of the plant. My proposed way of finding the electrical consumption for the design is to take the equipment section by section with a basis in mind. For example, if the gas which will be produced during production is 174000ft/hr, then a likely precipitator which can treat the gas will be operating at a power of 2-3kW. This value will also depend on the design type of the precipitator used. By doing this then we can get an idea of the total electricity consumption in the design of the plant.

Electricity is most time saved by using a diesel powered pump instead of electricity powered. This also needs to be considered during the calculation.